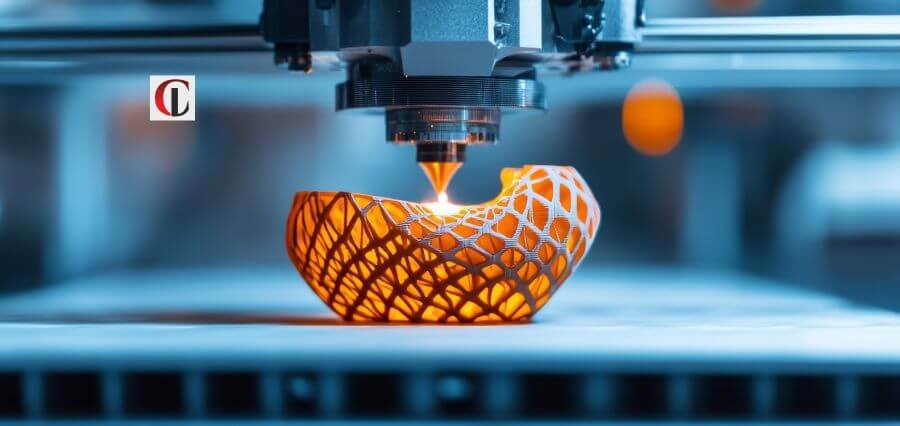

Additive manufacturing, or AM, is more commonly known as 3D printing. This technology is one of those which initially began as a niche and today transforms itself into an engine that runs through all sectors of the economy. Although developed with the sole intention of helping to create prototypes, AM has greatly progressed in materials, processes, and applications of designs in manufacturing and product distribution.

The Early Start and Slow Implementation

AM first started with stereolithography and selective laser sintering, the precursors of the current 3D printing technologies, during the 1980s. Innovations in hardware and software in the 2010s propelled AM to prominence, and it started its shift from prototyping to full-scale production.

Materials and Advance Processes

The most prominent step made in the last ten years of AM has been the growth of printable materials. While the first AM systems could only work with a few plastics and polymers, recent innovations have introduced metals, ceramics, composites, and bio-compatible materials. Printable materials can create wide-ranging applications that are possible through industries such as aerospace, healthcare, and automotive, to be able to use AM for high-performance, end-use parts.

Processes have diversified and, in electron beam melting, direct energy deposition, and material jetting methods, boundaries that define what has been possible have shifted. These technologies provided precision, speed, and scale to AM; hence, these have made them an alternative to the conventional methods used in complex, customized products in industries.

The Application in Diverse Industries

Aviation and Automobile Industry

The aerospace and automotive industries have been the first movers in adopting AM technologies. Aerospace companies use AM to produce lightweight, intricate components that reduce fuel consumption and enhance performance. Similarly, automotive manufacturers leverage AM to create custom parts, optimize designs, and accelerate the development of electric vehicles.

Healthcare and Biotechnology

Healthcare: applications of personalization in AM include individual prosthetics and implants and pre-surgical surgical guides, for instance. A giant step further could be towards feasibility of tissue, or even organ scaffolding. This would take the field toward regenerative medicine.

Consumer Products and Beyond

Consumer goods manufacturers have adopted AM for rapid prototyping and mass customization. It has changed customer expectations from customization in custom shoes to eyeglasses, tailoring products according to individual tastes and preferences. Thirdly, the construction industry has already started experimenting with 3D printed houses and other infrastructure, that is, with large-scale possibilities of AM.

Integration with Digital Technologies

One major game change was the integration of AM with digital technologies such as artificial intelligence (AI), Internet of Things (IoT), and generative design. The algorithms from AI enhance designs with performance and material efficiency, and IoT-enabled printers ensure precision and real-time monitoring. This advancement ensured that streamlined production workflows and reduced waste, thus AM became the heart of smart manufacturing.

Challenges and Opportunities

Despite the success AM has enjoyed to date, several challenges have to be addressed for it to fully realize its potential. These include very high costs for equipment, scalability problems for particular applications, and material availability. The other very important challenge is quality control and standardization, especially for aerospace and health applications where the level of accuracy and reliability becomes very critical.

However, such challenges open doors for innovation as well. R&D investment drives the cost downward and creates choices for the type of materials that could be used. The industrial cooperation allows creating standards and best practices; however, developments in hybrid manufacturing are opening doors by integrating additive with conventional techniques.

The Future

The coming decade will truly witness the acceleration of innovation in AM. Sustainable manufacturing, decentralized production, and 4D printing where objects adapt over time will transform the industrial landscape. When these AM technologies become more accessible and integrated into supply chains, they will be central to solutions for challenges such as decreased carbon footprint and on-demand manufacturing in remote locations.

Conclusion

The last decade is an evolution of additive manufacturing. With its transformative capability, it has really made tremendous strides into the future. AM has revolutionized the way industries function and presented new frontiers for innovation. Business and researchers harnessing its capabilities will ensure additive manufacturing remains at the forefront of the next industrial revolution.